Making Hoodies for the Team

The Art and Story Behind SLAM’s Bespoke Garments

I almost missed my flight to LA and it was 100% my fault. I woke up late, I didn’t pack the night before, and I got stuck in an egregiously slow airport shuttle.

My flight to LA started boarding 10 minutes ago. If there was even a sliver of a line at security, I risked missing my fight. And that would have been a bummer because I was excited about this work trip.

SLAM Ventures is undertaking a creative project involving the fabrication of custom clothing; I volunteered to go on the trip with our clothing expert, Jason Hong.

There is construction at SFO, so when I finally reached the terminal I was met by an unrecognizable maze. The TSA agent looked at my boarding pass and snapped at me, saying that TSA Pre is on the second floor.

Second Floor? Since when did TSA become a multi-floor endeavor? On the elevator up I nervously asked the girl next to me if she was also going to TSA Pre.

“I think so”, she answered timidly.

At this point, there was a 50-50 chance I’d miss this flight. The airport gods blessed me with a short queue, which I quickly got through and sprinted to my gate. I made it. Thank god. Jason was waiting for me at the gate.

“Where have you been man?”

“Sorry dude, traffic”, I gasped.

This was a lie. There was no traffic, I’m just a chronically late human being.

Before this trip, Jason and I didn’t know each other very well. But the dissolved tension of almost missing the flight fast-tracked our friendship.

The purpose of our trip was to visit clothing manufacturers in LA to begin making merch for SLAM Ventures. This merch is different from all other corporate merch; it’s going to be bespoke and be made just for SLAM.

Why do we want this? Wouldn’t it just be easier to buy blanks from an established brand? Yes, but that’s not what SLAM is about. SLAM’s ethos is that of an artisan, producing things of the highest quality out of a love for the craft. And that’s what we want our merch to be, the highest quality garment made with passion. That’s why we were on this plane to LA.

On the plane, as Jason filled me in on the details of the trip, I gained a deeper understanding of his passion for clothing; I finally understood why he didn’t want to buy blanks and embroider our logo on them. For him, buying a blank and sticking a logo onto it would be like a painter buying a coloring book and filling in the lines with crayons… it just wouldn't feel right.

This endeavor is purely one of passion, one to express ourselves and set our small team apart from the dozens of others, while basking in the satisfaction of wearing a piece that’s as bespoke as they come.

We landed in LA and took an Uber to a matcha place: Community Goods. I peered out of the Uber and saw a line of influencer types, I sighed and joined the queue. Jason started taking a video of me. Man, I hate being an influencer.

Finally, off to some business, we headed to Koreatown to meet a pattern maker. A pattern is a drawing that a pattern maker produces: it serves as a blueprint of the garment. Jason explained patterns, blanks, MOQ (minimum order quantities), and all sorts of other clothing jargon to me on our Uber from the Matcha place to Koreatown. He further elaborated on how we don’t want to buy blanks because the ethos of this project is complete customization, he then popped a neuro mint in his mouth, turned to me, and said that he wants to lock in this business trip.

The Uber driver dropped us off at a seedy-looking strip mall. I swiveled my head to discern my surroundings: I saw a strip club across the street, graffiti lining the walls of all the buildings, and boarded-up storefronts. Jason dramatically pointed to a shop on the second floor and said: that’s the one. We nervously trekked up the stairs. Jason greeted a man in his mid-sixties in Korean, who gestured to both of us to take a seat. I’d hoped the conversation would be at least partially in English, but the pair dove into a deep talk… exclusively in Korean.

The lack of English was a blessing in disguise, it allowed me to walk around the studio, and peer into the world of textiles: one of which I had no prior knowledge. I touched the spools of fabric, marveled at the sewing machines, and examined the patterns strewn across the main drafting table.

As the conversation finished, I turned back in the direction of Jason, who gestured to me to come outside.

“It’s not gonna happen”, he whispered to me in a somber tone.

“Why”, I interjected.

“He thinks I’m just a wide-eyed kid trying to launch a clothing brand; he suggested that I just buy blanks, and embroider my designs onto them.”

“Well, what do we do now?”

“He suggested a few other manufacturers for me to go see.”

We walked through a freeway underpass onto Santi Street in Los Angeles. The vibrant Latino neighborhood was filled with sights and smells that reminded me of the Mission District back home. Only this neighborhood had shop after shop of garment stores. Each of these stores sold miscellaneous items at a price a few bucks cheaper than what one would find on Amazon.

We entered our second factory, where we were greeted by a Southern European man in his mid-50s. We explained to him that we were trying to make merch for our startup, and he showed us samples of the fabric.

“How many hoodies are you looking to make”, he asked.

“50”, Jason replied.

“No can do, we do a minimum of 250 units for custom orders”, he explained.

He then went into how it isn’t worth the factory’s time to get set up for a custom pattern without making at least 250 of the same design. The money seems to be in the volume. He told us to get a pattern, buy some fabric, and go to a tailor if we wanted to make a small volume of product. I naively took his advice and asked Jason how we should go about finding a tailor.

Jason, while visibly frustrated, kept his cool and patiently explained that while our clothing is meant to be custom, it isn’t DIY. The craftsmanship must remain high, and while we will only do about 50 hoodies to begin with, the goal is to do a big batch. A tailor is a temporary solution to a bigger problem: we need to find a good manufacturer to test out our product at a small volume now so that we can produce at a larger volume later.

He called an Uber to another factory we were scheduled to visit. This next one is fancy, not like the ones before. There was a waiting room and fake plants lined the corners of the office. A quintessential LA lady comes to get us; she fake smiles at us, judges us based on our age, and condescendingly leads us through this magnificent warehouse.

The warehouse had 40-foot ceilings, the edges of the room were lined with conference areas and offices, while the center of the room was scattered with a dozen or so tailors hard at work on their sewing machines. Light spilled through the double pane honeycomb windows into the center of the room: it was beautiful.

Ms. Hollywood continued explaining the exorbitant pricing plans associated with manufacturing at this factory; just to get started with a few samples costs a pretty penny. She name-dropped designer brands that chose to make clothing here and led us upstairs to the most glamorous conference room of them all. Jason asked her relevant questions about their manufacturing process and other garment-related specifics. All the while, I felt this undertone of unseriousness coming out of her voice, one instilling a vibe that we aren’t good enough to make our clothes here.

We finally left, wholly dejected that we had traveled hundreds of miles, and met with 3 manufacturers and all of them gave us the same answer: we can’t make your thing here. We hopped into an Uber, and headed to our last hope and final stop of the trip.

We stepped out of the car and walked around this final block looking for someone named Gio. Jason went up to a group of people washing cars, and asked them, “We’re looking for Gio!”.

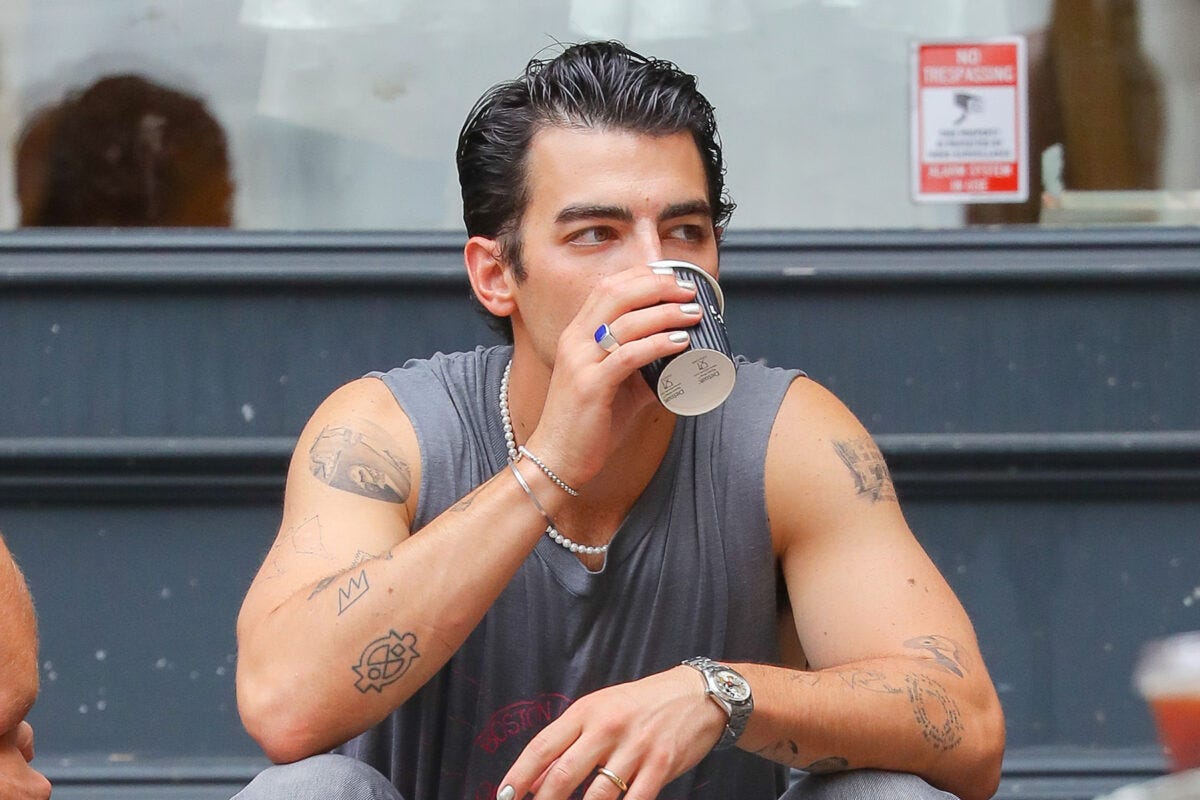

They pointed us toward a set of silver doors and were let in by a man in his 30s. He had a well-groomed beard, dozens of tattoos on his forearms, and was wearing a Rolex Submariner with a rugged cloth strap on his wrist. He looked like a pretty cool motherfucker.

“We’re looking for Gio”, Jason said.

“That’s me”, he replied.

I was internally surprised. I was expecting Gio to be a grumpy 65-year-old man, but instead, he had this chill Rolex-wearing Hipster vibe.

“I’m Jason”

“I’m Raj”, I blurted out as an afterthought.

“Oh, welcome guys it’s nice to meet you”, Gio warmly responded.

He led us through a warehouse not as polished as the one before, but weirdly seeming of higher quality, kinda like a Carhartt jacket you know. We spoke in the back room, and Jason gave him the same spiel that he gave to the others: custom clothing, small batch, but with the potential for lots of expansion. As the grand finale, Jason pulled out one of his favorite hoodies and looked Gio in the eye.

“I like this hoodie, it’s my inspiration for making our own”, he said.

“Oh nice, yeah we make that hoodie here, and I designed that fabric myself”, Gio responded while simultaneously running his fingers across the seam of the garment.

I’d like to double-click on how much of a coincidence this is. There are tens of thousands of clothing factories in the US, and an order of magnitude more hoodies that Jason could have based his design off. But here we were, in the factory that made the hoodie that we love so much.

It was destiny.

Gio was warm to us before, but after we showed him his hoodie, there was a new feeling of comradery. Also, on the logistical side, it would be comparatively easy for Gio to work our product into his factory now that we revealed our preference for a style and fabric that he is deeply familiar with.

After we worked out the details, he offered us a tour of his factory.

We walked through the first floor, which was littered with people hard at work on their sewing machines. We exited through the silver doors that we originally walked in through, and took a flight of stairs up to the second floor.

As we walked through an assortment of things I can only describe as “textile manufacturing equipment”, he told us about how he built this factory from the ground up and how this represents everything he’s worked for: there was a look of pride in his eyes. I liked him a lot more than Ms. Hollywood.

I asked follow-up questions about how he keeps up with demand, why he has a factory in LA, and what the plan is for the future. He explained that his offshore facilities can quickly ramp up for high volume, while the factory in LA is for quick turnaround sampling.

I looked around and was so impressed. Because I saw a humble man, who built a business from the ground up, provided good-paying jobs for people in his community, and did what he loved.

We finalized a plan to get moving on the hoodies. As we left the factory, Jason jumped in excitement.

“Let’s fucking goooo”, he shouted excitedly.

In the Uber back to the airport, I looked Gio up and was so inspired by his story. He started designing clothes out of his dorm and posted a T-shirt design on Tumblr. He woke up to a viral post with comments from A-List celebrities. He skated down to the garment district and tried to figure out how to make that shirt.

Gio slowly but surely got deeper into the details of manufacturing clothes; in search of the perfect factory, he decided to start his own. At 22 years old he opened the Mancini factory, without taking on outside investment. More than a decade later that factory has grown into a business with a home in LA and multiple factories across the globe. The humility that he showed us despite all his success is a testament to his character.

These SLAM hoodies led us to a person who inspires us, it's crazy how creative pursuits lead you to the most interesting people. I bet when Gio started his factory he also just wanted to be an artisan, and make good clothes that he was proud of.

I’m taking a page out of Gio’s book going forward.

And honestly, I think we all should. Build good things, and do good along the way.

-Rajveer